Researchers affiliated with Boeing have produced what they claim to be the lightest metal ever made. It’s called “microlattice,” and the reason it’s so light is because it’s 99.99% air.

Sophia Yang, research scientist in architected materials at HRL Laboratories, a joint venture that Boeing is involved in with General Motors, calls it ”the world’s lightest material.” It’s an open-cellular polymer structure, made of interconnected hollow tubes, in three dimensions.

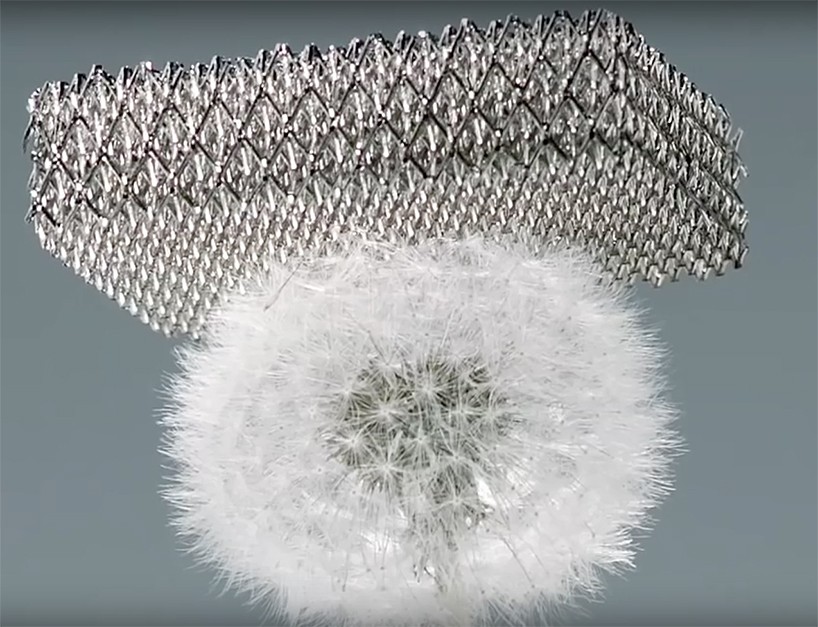

Yang compares its structure to bone, with a rigid skin and mostly hollow honeycomb interior. Bones are rigid and strong, as we know, but they also have a degree of flexibility due to the presence of collagen, and are relatively light. In the case of microlattice, the tubes that create the lattice structure are so thin, they look like tiny wires, with a wall thickness of 100 nm, which is 1,000 times thinner than a human hair. In HRL’s promotional image, a small block of the material is shown balanced atop a dandelion.

The material, besides being extremely light, has some remarkable mechanical characteristic

s. Among these are its ability to completely recover from compression exceeding 50% strain. It also offers extraordinaril

y high energy absorption.